ROTATIONAL MOLDING

Our Rotational molding capabilities consists of 3 machines that operate twenty four hours per day. Part weights range from 1 to 350 pounds and up to 750 gallon tank sizes. Materials that we do process include, LLDPE, Crosslink HDPE, and Polypropylene. We have many dry blended pigments in stock to choose from or a custom color can be formulated.

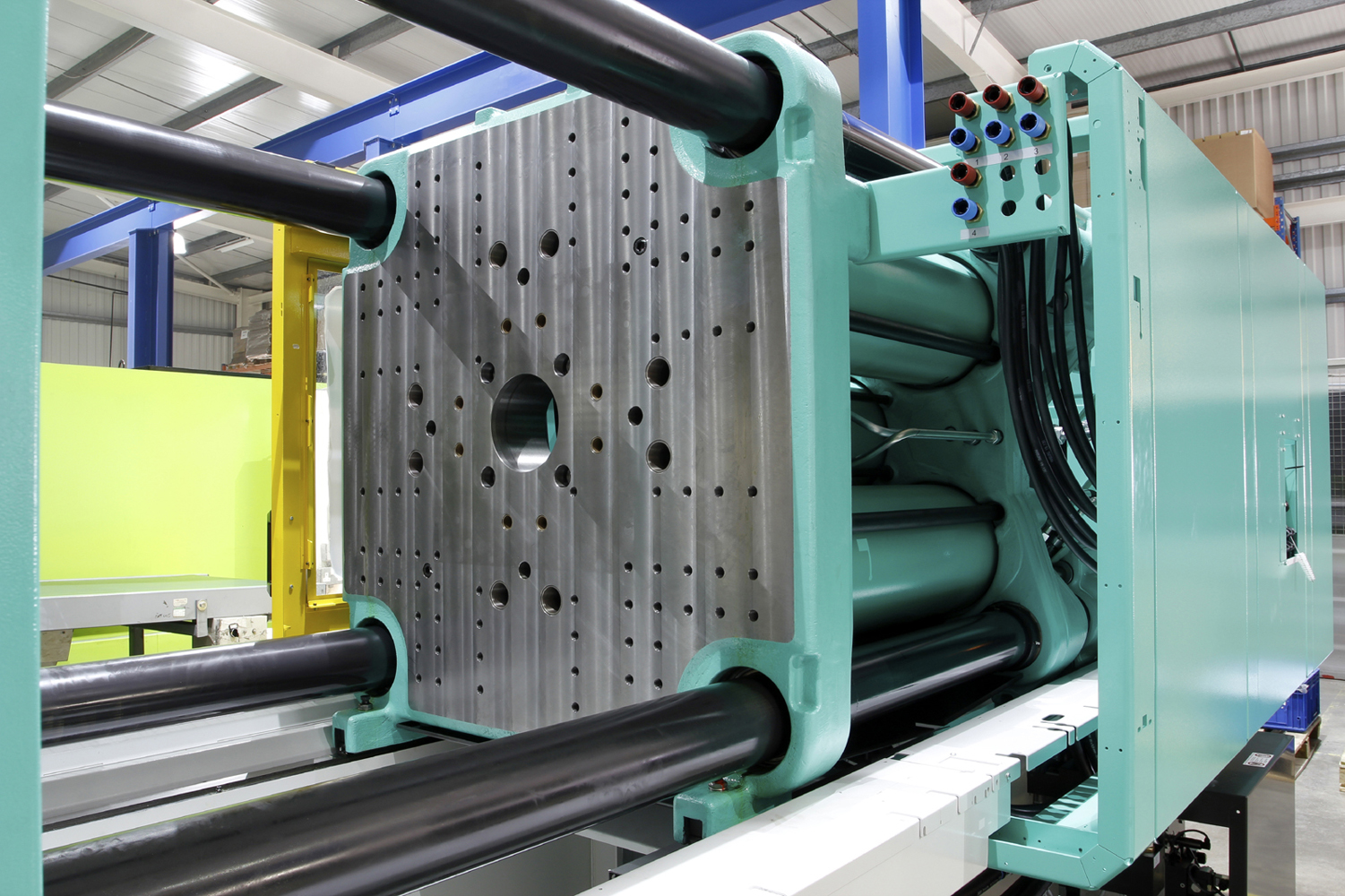

INJECTION MOLDING

The Injection molding department is fully equipped with late model material, drying, conveying equipment, and press tonnage of 150 to 300 ton.

MACHINING

We currently have four employees on hand in the tool building & machining department producing Billet CNC Molds for Rotational and Injection molding projects. The machine shop is equipped with (1) full five axis CNC Mill, (2) three axis CNC Mills, (1) CNC Lathe, (1) CNC Wire EDM, (1) CNC Plunger EDM, and various support equipment.

CAD DESIGN / ENGINEERING

Our Cad department utilizes Solid Works software with many years of Rotational Molding and Injection Molding experience to draw from. We can work from a sketch on a napkin or from your own CAD file. We pride ourselves in incorporating as many features into the design as possible, knowing the importance to our customers.

FABRICATION

Our fabrication department is equipped with metal forming, shearing and welding equipment. Along with many years of experienced fabricating and repairing roto molds.